GE Aerospace’s Q2 Performance: A Closer Look at a Stellar Quarter

In an impressive display of resilience and execution, GE Aerospace reported a stellar second quarter and first half of 2025. Their Q2 profit shot up by 65% to $2.4 billion, while total revenue surged 21% to $11.0 billion. The profit margin also saw a significant boost—from 15.9% a year ago to 21.7%—a transformative 37% improvement. In many ways, these numbers echo the broader shifts in the aerospace and manufacturing sectors, where companies must steer through tricky parts and tangled issues to deliver robust financial and operational performance.

By pairing its earnings release with a detailed Investor Update, GE Aerospace aimed to give investors and industry watchers a comprehensive overview of its progress. Initially planned for the Paris Air Show, the update was postponed following a regional aviation incident, underscoring how external events can complicate even the best-laid plans. Nonetheless, Chairman and CEO Larry Culp emphasized the company’s confidence by noting that GE Aerospace powers three out of every four commercial flights, with Commercial Engines & Services (CES) running more than 49,000 engines in service, and counting.

GE9X Engine: Pushing the Boundaries of Testing and Certification

The journey toward the entry-into-service of the GE9X engine has reflected the challenging, often nerve-racking twists and turns that come with high-stakes innovation. Tied initially to the delayed Boeing 777X program, the GE9X now stands as the most advanced and the most extensively tested engine in GE Aerospace’s history.

Extensive Testing: Passing the Ultimate Exam

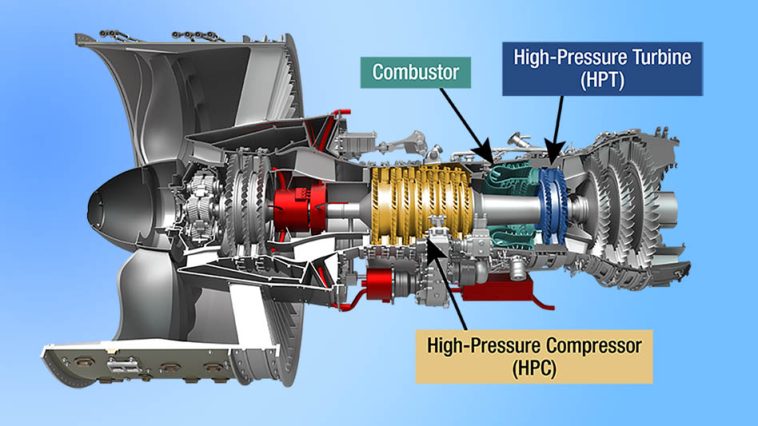

GE Aerospace is not leaving anything to chance. The GE9X has endured over 30,000 test cycles and 8,000 endurance cycles, including more than 1,600 hours in particularly hot and harsh conditions—equivalent to six years of continuous commercial flying. This rigorous testing has allowed engineers to get into the fine points of the design, making intricate enhancements such as the second iteration of the high-pressure turbine (HPT) blades. In doing so, GE ensures that the GE9X is as mature and ready for real-world operation as possible at the time of launch.

Market Reception: Positive Customer Sentiment Amid Challenges

Customer sentiment around the GE9X remains positive. GE Aerospace recently witnessed a 60% win rate in engine selections versus competitors—a sign of the brand’s strong reputation amid an industry filled with confusing bits and delays. With a massive backlog of over a thousand engines, and significant orders from major carriers such as Qatar Airways and Air India, the demand for GE9X is a critical component of GE’s long-term strategic outlook. These orders not only represent confidence in the technology but also signify that GE Aerospace is on the right path to deliver the next batch of cutting-edge engines.

Innovations in Engine Design: Lessons from LEAP and GEnx

Alongside the GE9X initiatives, GE Aerospace’s LEAP and GEnx engine programs continue to drive forward innovation and efficiency, touching both widebody and narrowbody aviation markets. A comprehensive understanding of these programs is essential in appreciating how GE Aerospace is leveraging its expansive experience to manage complicated pieces in a competitive environment.

LEAP Engine: Proving Its Mettle as Service Demands Grow

Since its debut in 2016, the LEAP engine has been steadily climbing the ranks to become one of the highest-volume commercial engine programs in the world. With more than 9,000 units now operational across Airbus A320neo and Boeing 737 MAX fleets, LEAP proves that learning from past widebody projects can translate into similar gains for narrowbody operations. The engine’s performance is being dramatically enhanced by the recent introduction of a new durability kit that includes upgraded HPT blades. This innovation is set to more than double the time-on-wing for the -1A variant, bridging the performance gap with legacy engines like the CFM56.

Some key points on the LEAP program include:

- Year-over-year new engine deliveries increased by 38% in Q2.

- First-half 2025 deliveries grew by 10% compared to the previous year.

- GE remains confident in delivering 2,500 LEAP engines by 2028.

While retrofitting the over 9,000 installed LEAP engines remains a long and complicated process, GE maintains that the retrofit will be completed gradually during scheduled shop visits. Certification for the LEAP-1B durability kit is expected in the first half of 2026, enabling a phased integration strategy spanning production through to the aftermarket. This measured approach ensures that updates can be applied without disrupting the service schedules of the many airlines that rely on these engines.

GEnx Engine: Championing Durability and Efficiency in the Widebody Market

The GEnx engine has long been GE Aerospace’s cornerstone in powering Boeing 787 aircraft. Its robust time-on-wing performance and excellent durability have helped maintain a market-leading position, with more than 60% of the global Boeing 787 fleet running on this technology. Innovations such as the durability package, revamped back in 2021, have more than doubled the engine’s time on wing, which in turn means fewer disruptions and maintenance events for airlines operating under challenging conditions.

Highlights of the GEnx program include:

- A significant increase in service cycle performance, now approaching 4,000 cycles in harsh environments.

- Reduction in maintenance intervals, enabling engines to remain operational for approximately five years between shop visits.

- Maintaining a strong win rate (over 90%) in engine selections for the Boeing 787 since 2023.

These improvements provide airlines with the confidence that their capital-intensive widebody fleets can operate reliably with minimal downtime—a critical factor in the highly competitive commercial aviation market.

The Promise of RISE: A Bold Leap into Open Fan Technology

The RISE program represents GE Aerospace’s most ambitious venture in recent memory. With a focus on open fan, or unducted, engine technology, RISE is poised to revolutionize fuel efficiency and overall engine performance, particularly for next-generation narrowbody aircraft.

Revolutionary Design: A Paradigm Shift for Narrowbody Propulsion

Designed to achieve at least a 20% reduction in fuel burn compared to current LEAP engines, RISE operates on the philosophy that pushing for efficiency doesn’t solely rest on enhancing thermal performance. Instead, by focusing on fan system performance, RISE shifts the efficiency balance. The open fan architecture allows the engine to operate at a lower rotational speed—about 60% of that of traditional designs—which not only improves safety but also results in quieter operation.

This approach is particularly key in addressing the nerve-racking challenges that come with conventional throttling of cores to higher temperatures. By reducing core temperature requirements, GE can potentially mitigate many of the tricky parts and complicated pieces of engine overheating and retrofitting issues that have plagued earlier designs.

Testing Ground: Proving the Concept Through Rigorous Trials

GE Aerospace’s RISE program has already completed over 350 detailed tests focused on durability and performance. This includes rigorous testing of full-size fan blades, advanced HPT blade cooling technology, and more than 3,000 endurance cycles. The results so far are promising, but GE remains cautious, noting that RISE is a multi-year effort that spans ground testing, flight testing, and extensive integration with engine and airframe systems.

Key elements driving RISE’s potential include:

- Innovative fan system integration designed to minimize the need for aggressive core temperature increases.

- Enhanced safety features, such as slower fan speeds, which contribute to overall flight safety—even in the absence of a traditional nacelle.

- Quiet engine operation that might also pave the way for improved passenger comfort in future aircraft designs.

Managing Supply Chain and Tariff Challenges in a Competitive Landscape

Despite the impressive engineering milestones, GE Aerospace is not immune to the external pressures that shape today’s global aviation market. From supply chain unpredictabilities to significant tariff burdens, the company faces several tricky parts as it works through economic and geopolitical tensions. These factors are loaded with issues that require careful strategic management.

Supply Chain Improvements: Learning to Work Through the Complicated Pieces

Over the last year, GE Aerospace has implemented a new operating system known as FLIGHT DECK, along with a revised organizational structure aimed at boosting supply chain performance. CEO Larry Culp highlighted the success of these initiatives, noting improvements in supplier execution that have seen critical suppliers delivering on commitments in the 95% range. This improvement in execution—documented with both percentage increases and performance metrics—demonstrates that GE is getting around some of the most overwhelming parts of a global supply chain.

The company now collaborates more constructively with its suppliers, which not only addresses the supply chain’s inherent unpredictable elements but also nurtures a more stable and reliable delivery rhythm. Culp’s observation that the atmosphere has shifted from one of uncertainty just a year ago to a more constructive and collaborative approach underscores the fact that even in an industry full of confusing bits and nerve-racking delays, breakthroughs are possible with the right partnerships.

Tariff Impacts: Bracing for a $500 Million Headwind

Tariffs remain a persistent and considerable burden for GE Aerospace in 2025, posing a significant challenge that is both intimidating and off-putting. As the company braces for potential reciprocal tariff measures between the United States and China, it expects a net impact of roughly $500 million for the year. Despite these additional costs, CFO Rahul Ghai confirmed that GE’s operational and mitigation plans are well on track to manage this headwind.

The company’s approach to tariff-related challenges features:

- Focused strategies to shore up the supply chain and reduce the effects of increased input costs.

- An emphasis on the aftermarket segment, where conditions have remained relatively favorable due to the absence of reciprocal tariffs in China.

- A broader policy stance supporting free and fair trade, which GE argues has fueled the growth of the U.S. aerospace sector, contributing to over 1.8 million U.S. jobs and a $75 billion annual trade surplus.

Financials and Future Outlook: Growth Amid Economic Complexity

GE Aerospace’s financial performance has been impressive, marked by blow-out quarter results and raised forecasts for both the near and long-term horizons. In addition to the healthy quarterly revenue and profit increases, the company has also elevated its outlook for future performance, with expectations for operating profit growth that extend into 2028.

Record-Breaking Quarterly Results: A Snapshot

The propulsion maker’s second quarter delivered concrete evidence of market strength. Key financial highlights include:

| Metric | Q2 2025 | Q2 2024 | Remarkable Change |

|---|---|---|---|

| Profit | $2.4bn | ~$1.46bn (Approx.) | +65% |

| Total Revenue | $11.0bn | ~$9.1bn (Approx.) | +21% |

| Profit Margin | 21.7% | 15.9% | +37% improvement |

Within CES alone, second-quarter revenue climbed by 30%, with services revenue increasing by 29% and equipment revenue rising by 35%—indicating both volume and pricing improvements. These impressive numbers reflect the company’s ability to figure a path through the opaqueness of an ever-changing market.

Revised Financial Guidance: What Lies Ahead

Encouraged by the first-half performance, GE Aerospace has revised its full-year guidance. The forecast now includes operating profit in the range of $8.2 to $8.5 billion—an increase of roughly $1 billion over 2024 expectations. Additionally, the long-term forecast for 2028 has been elevated by $1.5 billion, reaching an anticipated operating profit of $11.5 billion, demonstrating robust confidence in continued market growth.

CEO Larry Culp emphasized that these upgraded forecasts signal not just short-term recovery but long-term, sustainable success. This confidence is built on several factors, including continuous improvement in manufacturing, design innovation, and a yield-enhancing supply chain model. As GE Aerospace moves forward, it is fully prepared to tackle the remaining intimidating bits and tangled issues that may crop up along the way.

Together with Customers and Partners: Building a Resilient Ecosystem

GE Aerospace’s achievements over the past quarter are not solely a testament to in-house operational improvements. They also reflect a broader commitment to collaborative excellence. In an industry where partnerships are as crucial as technological breakthroughs, the company’s collaboration with major airlines and suppliers has been a key influencer in its success.

Customer Engagement and Feedback: Shaping the Future of Engine Design

Customer sentiment is a primary indicator of a successful product launch. In the case of both the GE9X and LEAP engines, GE Aerospace has worked closely with airline operators to gather real-time feedback and incorporate that input into design and service enhancements. Positive remarks and a rising win rate against competitors indicate that customers appreciate the meticulous attention to detail and the proactive approach that GE takes in addressing safety and performance concerns.

This level of engagement helps the company to not only launch cutting-edge technologies but also to maintain a consistent improvement cycle, addressing minor twists and turns that come with operating complex machinery. For many operators, this collaborative approach is a reassurance that their investments are not just in products but in a longstanding partnership that values safety, efficiency, and technological evolution.

Partnering with Regulatory Agencies: Balancing Innovation and Safety

Another crucial aspect is GE Aerospace’s interaction with regulatory bodies such as the Federal Aviation Administration (FAA). While there have been concerns flagged with components like the LEAP-1A high-pressure turbine parts, GE’s solution-focused approach—centered on upgrades and durability kits—ensures that safety remains paramount. In a field where even minor tweaks can have major consequences, GE is meticulously ensuring that each engine not only meets but exceeds the criteria laid out by oversight agencies.

This careful balance of innovation with compliance is a testament to GE Aerospace’s commitment to quality and safety across its entire portfolio. By addressing even the subtle details in the design and testing phases, GE is paving the way for smoother certification and higher market confidence, despite the nerve-racking hurdles that sometimes arise.

Industry Implications: A Broader Perspective on Aerospace Innovation

GE Aerospace’s Q2 performance and its forward-looking projects are not isolated successes. Instead, they are reflective of larger trends and shifts within the global aerospace market. As manufacturing rises to meet modern demands, and as airlines look to reduce operational costs and increase durability, the entire industry stands to benefit from the innovations championed by companies like GE Aerospace.

Impact on Industrial Manufacturing and Technology Integration

The evolution of engine technology—from the GE9X to the RISE program—is having a significant knock-on effect on industrial manufacturing. Innovations in high-precision testing and engineering design are pushing the entire sector toward higher efficiency and sustainability. The careful orchestration of engineering, supply chain management, and customer engagement has created a template that other industrial manufacturers may well wish to emulate—a balance of technical rigor with consumer-centered design and responsiveness.

Key benefits include:

- Enhanced operational efficiency through advanced testing and quality assurance.

- Reduced maintenance overheads as engineering improvements extend the time on wing.

- Improved customer satisfaction driven by transparent communication and collaborative enhancements.

Industrial sectors beyond aerospace can learn from the way GE Aerospace tackles the tricky parts of product development, the tangled issues of supply chain management, and the overlapping challenges of global market pressures. Such cross-industry learning fosters deeper partnerships and innovative solutions that benefit the broader manufacturing ecosystem.

Automotive Parallels: From Engine Durability to Hybrid Efficiency

While GE Aerospace’s engine programs are focused on accelerating performance in the skies, the strategies they adopt often find parallels in the automotive sector. Just as GE is investing in cutting-edge technology to ensure engine durability, automotive manufacturers continuously strive to increase engine efficiency and longevity in a competitive market. Both sectors face similar challenges—tackling overwhelming technological upgrade cycles and managing market expectations amid regulatory restrictions and global tariffs.

The open fan design in the RISE program, for instance, might inspire similar approaches in electric vehicle motor design, where efficiency gains are critical. The drive to simplify complex systems, whether in aircraft engines or car drivetrains, is a common thread binding disparate industries together in the pursuit of performance excellence.

Marketing in the Digital Age: Leveraging Financial Success for Brand Momentum

Financial performance and technological innovation are only part of the equation. In today’s fast-paced business environment, marketing must also evolve to communicate these successes effectively to customers and stakeholders. GE Aerospace’s impressive Q2 numbers provide a compelling narrative—one that should not only reassure investors but also serve as a magnet for future partnerships and commercial deals.

Crafting a Narrative: Financial Success as a Marketing Lever

For companies operating in highly technical sectors, translating complex performance metrics into accessible stories is both an art and a necessity. GE Aerospace has managed to do this by emphasizing the tangible benefits of its technological innovations—improved reliability, extended time-on-wing, and stronger economic forecasts. These elements form the building blocks of a narrative that captures both the financial and technical facets of modern aerospace engineering.

Key elements include:

- The transformation of Q2 performance figures into a narrative of resilience.

- Customer success stories that highlight real-world benefits from enhanced engine durability.

- Industry comparisons that underline GE Aerospace’s edge over competitors in both technology and service delivery.

By articulating these themes clearly, GE not only helps customers and partners understand its value proposition but also positions itself as a thought leader in a crowded and competitive market. This strategic narrative can be a powerful tool for driving new business initiatives, enhancing market share, and ultimately contributing to long-term growth.

Digital Engagement and Thought Leadership

In the digital age, reaching target audiences requires more than just good old-fashioned press releases. GE Aerospace has been increasingly adept at using digital platforms to disseminate its financial and technical news. Their robust online presence—bolstered by platforms such as industry-specific blogs, social media outlets, and targeted email campaigns—ensures that messages regarding their technological leaps and financial successes are shared widely.

This digital engagement strategy not only strengthens GE Aerospace’s brand identity but also builds a community of stakeholders who are consistently in the loop. As the digital landscape continues to evolve, companies that can effectively communicate their value will find themselves with a significant competitive advantage.

Looking Ahead: What GE Aerospace’s Future Holds

The journey undertaken by GE Aerospace in 2025 is one marked by innovation, operational resilience, and strategic efficiency. From the testing of the most advanced engines in history to managing tariff headwinds and supply chain challenges, the company’s story is one of overcoming overwhelming obstacles and unlocking new possibilities in aerospace engineering.

Charting the Path Forward in Innovation and Profitability

Moving into the future, GE Aerospace is poised to ride a wave of continuous improvement. The company expects the GE9X program to become profitable as it transitions into the 2030s—a trajectory similar to what was experienced with the LEAP engine program. Meanwhile, cost-reduction measures that aim to reduce production expenses by as much as 30% by the 50th unit, and another additional 30% by the 250th engine, set a clear path towards stronger margins and enhanced profitability.

The financial guidance has been further uplifted with the anticipation that, despite near-term profit headwinds—expected to be a couple of hundred million dollars in 2025—the overall outlook remains extremely positive. With operating profit projections for 2028 expected to exceed those of 2025 by more than $3 billion, GE Aerospace signals that it is well-prepared to tackle both the subtle details and the major, overwhelming challenges that lie ahead.

Building a Resilient and Adaptable Company Foundation

At its core, GE Aerospace’s success in this period of rapid change lies in its ability to work through complicated everyday challenges while simultaneously taking bold steps into uncharted technological territory. The company’s leadership is focused on not only refining its current operations but also investing heavily in next-generation platforms like RISE. This forward-thinking approach illustrates that GE Aerospace is taking a dual-track approach—meeting today’s demands while also setting the stage for tomorrow’s breakthroughs.

As the company continues to work through supply chain improvements, manage tariff impacts, and deliver on the solid performance of its diverse engine portfolio, it is clear that GE Aerospace is well-equipped for the uncertainties ahead. With a commitment to transparency, quality, and technical innovation, the company is not only making its mark on the aerospace industry but is also redefining the benchmarks for what is possible in propulsion technology.

Concluding Thoughts: Innovation, Resilience, and Partnership as the Keys to Success

GE Aerospace’s recent performance and forward strategy offer a master class in how to steer through tricky parts and complicated pieces in a highly competitive, global industry. Their relentless pursuit of technical excellence—whether it is through the exhaustive testing of the GE9X engine, the robust advancements in the LEAP and GEnx engines, or the revolutionary steps taken with the RISE program—demonstrates a dedication to addressing every small twist and challenging bit that comes along.

Moreover, the company’s capacity to find its way through tangled issues in supply chain management and tariff impacts is both admirable and instructive. It serves as a potent reminder that success in today’s business environment requires a balanced focus on technology, operational excellence, and strategic financial management. GE Aerospace’s story is not just one of impressive quarterly numbers or refined engineering—it is a narrative of effective collaboration with customers, regulatory agencies, and partners.

As the industry continues to evolve, the lessons from GE Aerospace’s endeavors offer valuable insights not only for other players in the aerospace and industrial manufacturing sectors but also for automotive and electric vehicle companies that face their own overwhelming and intimidating challenges. Whether you are a stakeholder, engineer, or industry analyst, keeping a close eye on these developments provides a window into the future of high-stakes engine innovation and global market dynamics.

Key Takeaways for the Broader Industry

To sum up, GE Aerospace’s approach over the past quarter—and its plans moving forward—can be encapsulated in several essential points:

- Comprehensive Testing: The GE9X exemplifies how extensive testing and attention to intricate details can yield a robust, market-ready product.

- Incremental Innovation: The ongoing refinements in the LEAP and GEnx engines show how learning from past projects accelerates performance in newer designs.

- Bold New Ventures: The RISE program highlights a willingness to challenge industry norms and embrace revolutionary strategies that focus on efficiency and safety.

- Supply Chain Mastery: Improving supplier performance and deploying advanced management systems like FLIGHT DECK illustrate the power of collaborative supply chain optimizations.

- Balanced Financial Strategy: Despite tariff headwinds and market fluctuations, GE’s upgraded financial forecasts and strategic cost reductions remind us that sound financial management is key to long-term resilience.

These takeaways serve as both a blueprint and an inspiration for companies navigating the nerve-racking complexities of modern global markets. By acknowledging both the minor details and the major strategic steps, GE Aerospace has positioned itself as a leader in an era defined by continuous change and evolving challenges.

The Future Landscape: Technology, Trade, and Transformation

Looking forward, the large-scale shifts in the aerospace industry signal a period of remarkable transformation. Companies are now expected to manage not just the fine points of engineering and manufacturing, but also steer through the broader economic and trade-related twists and turns. For GE Aerospace, the enhanced partnerships, improved supplier performance, and a balanced outlook between innovation and cost reduction collectively point to a vibrant future.

In a climate that is both thrilling and tense, GE Aerospace’s approach demonstrates that with the right blend of technical expertise and proactive management, even the most overwhelming challenges can be turned into opportunities for growth. Their story is a reminder to the broader industry that progress is not a straight line—it is a journey filled with unexpected turns, subtle adjustments, and the persistent drive to innovate despite external obstacles.

Final Reflections

GE Aerospace’s journey through Q2 2025 and its ambitious plans for the future stand as a testament to the power of ingenuity, resilience, and smart strategic planning in the face of daunting market conditions and regulatory challenges. With rigorous testing regimes, breakthrough innovations in engine design, and a willingness to challenge traditional paradigms with bold initiatives like the RISE program, GE Aerospace is not just keeping pace with industry evolution—it is actively shaping its future.

The detailed attention to every little twist and every small distinction in both the engineering and financial domains underscores the necessity of working through both trivial and overwhelming issues. As GE Aerospace continues to negotiate tariff headwinds, streamline its supply chain, and maintain robust financial health, industry observers and stakeholders alike would do well to take note of its comprehensive approach.

In closing, the story of GE Aerospace is more than just a series of impressive numbers or groundbreaking technological developments—it is a narrative of sustained progress, collaborative success, and a forward-thinking attitude that many businesses can look to as a model. Whether you are an engineer navigating the challenging parts of advanced engine technology, an investor looking for stable yet promising opportunities, or a policy maker keen on promoting fair and efficient trade practices, the lessons from GE Aerospace’s latest strides offer valuable insights into the future of global aerospace innovation.

Originally Post From https://leehamnews.com/2025/07/17/ge-aerospace-soars-on-commercial-momentum-in-q2-updates-on-ge9x-genx-leap-and-rise/

Read more about this topic at

Interactive Brokers: Volatility Is Supercharging Commercial …

Why Is AAR (AIR) Stock Soaring Today